Thermosealing machines

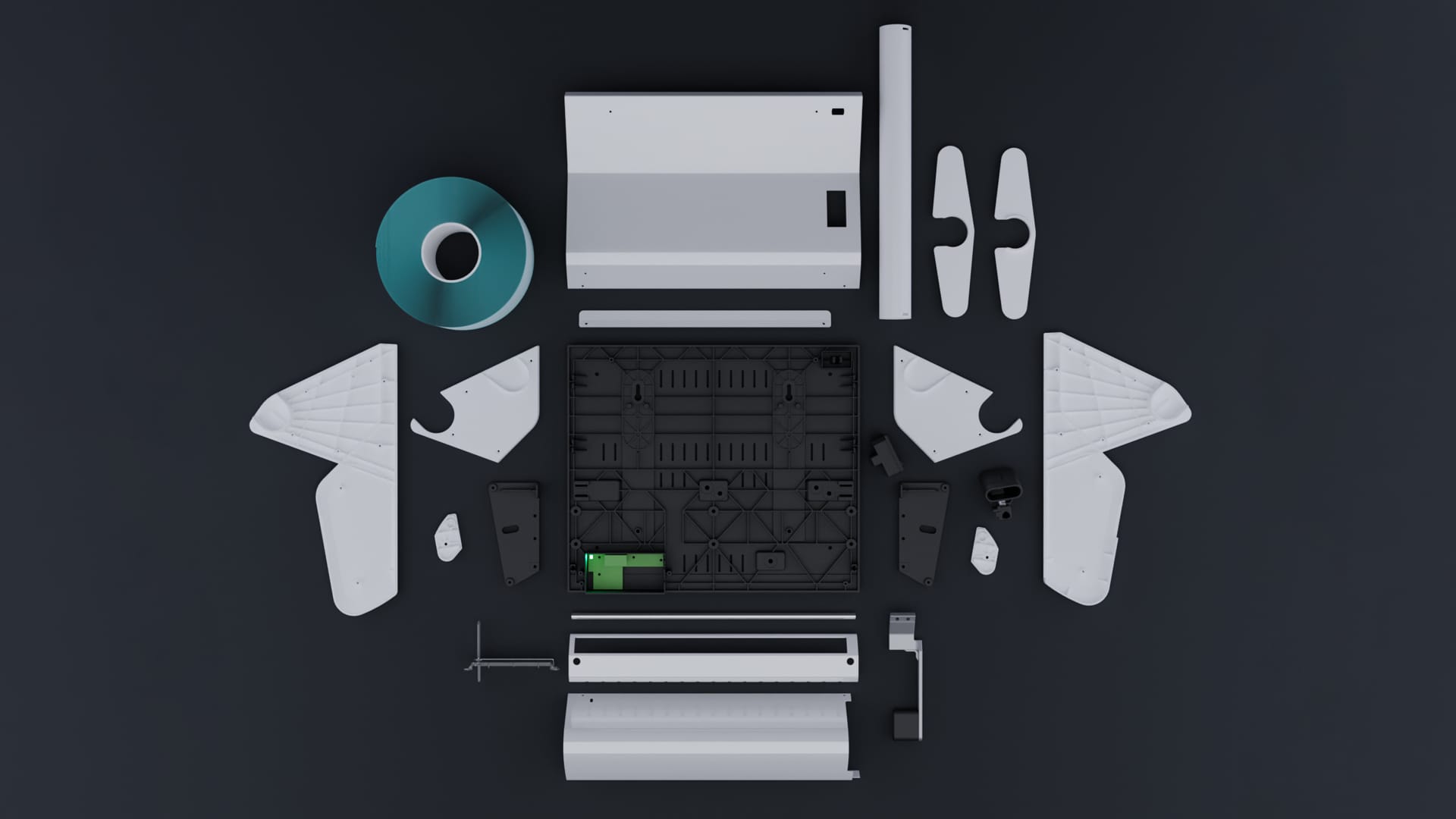

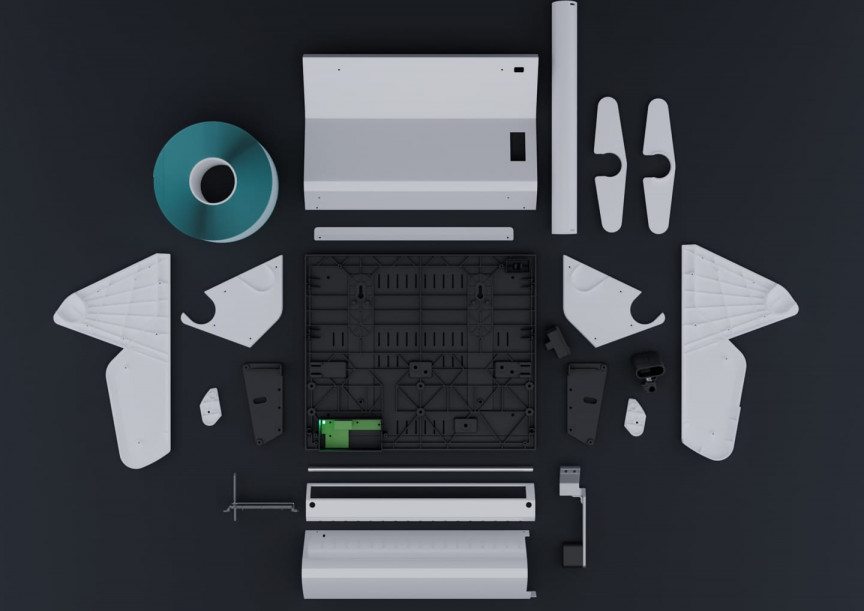

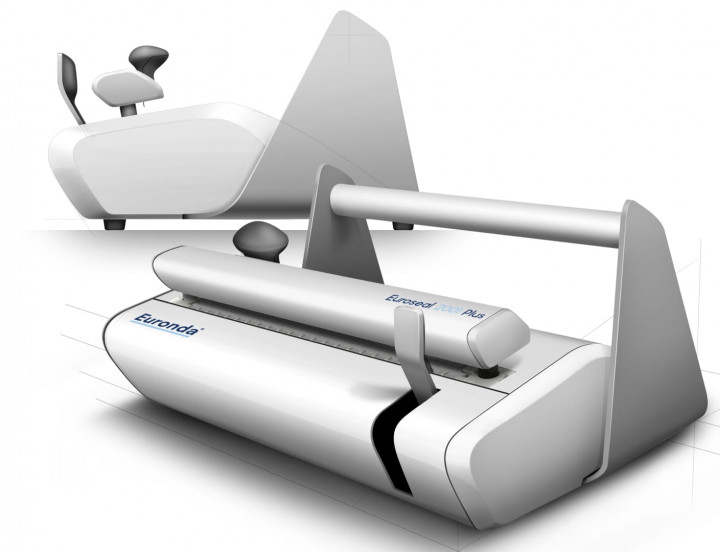

A leading manufacturer of disposable products for dental clinics and systems for the sterilization process based in Vicenza, has involved us in the restyling of a popular thermosealing machine.

The goal was to create, design and industrialize a new machine keeping the values of the previous model and building upon its key elements.

The project

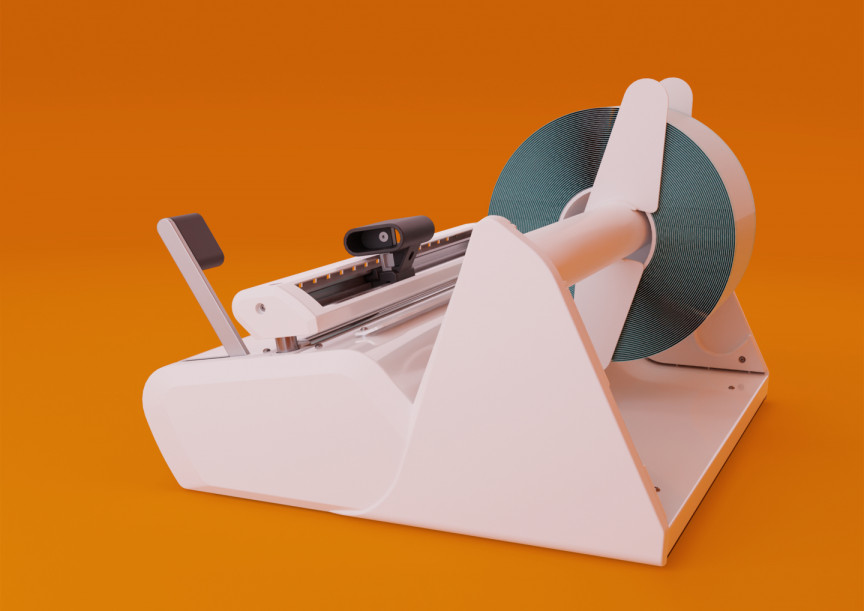

Robust, reliable and easy to use, the new design is soft and sinuous with the roll support elements that intersect seamlessly with the machine body. The soft surfaces also contribute to improving its functionality. The new built-in cutter and sealing lever positioned at the front not only improve ergonomics and safety but also make packaging and sealing operations easier.

Particular attention has been given to the cutting knob, with a design that marries the renewed style and at the same time is ergonomic and allows to implement the new system for the blade replacement which makes the operation simpler, faster and safer.

The dual hooking system of the roll holder tube allows to insert the rolls in the tube or to place them on top of it for greater convenience for replacement. This design makes the machine compact so it can be comfortably placed on a table top or wall-mounted in a vertical position.